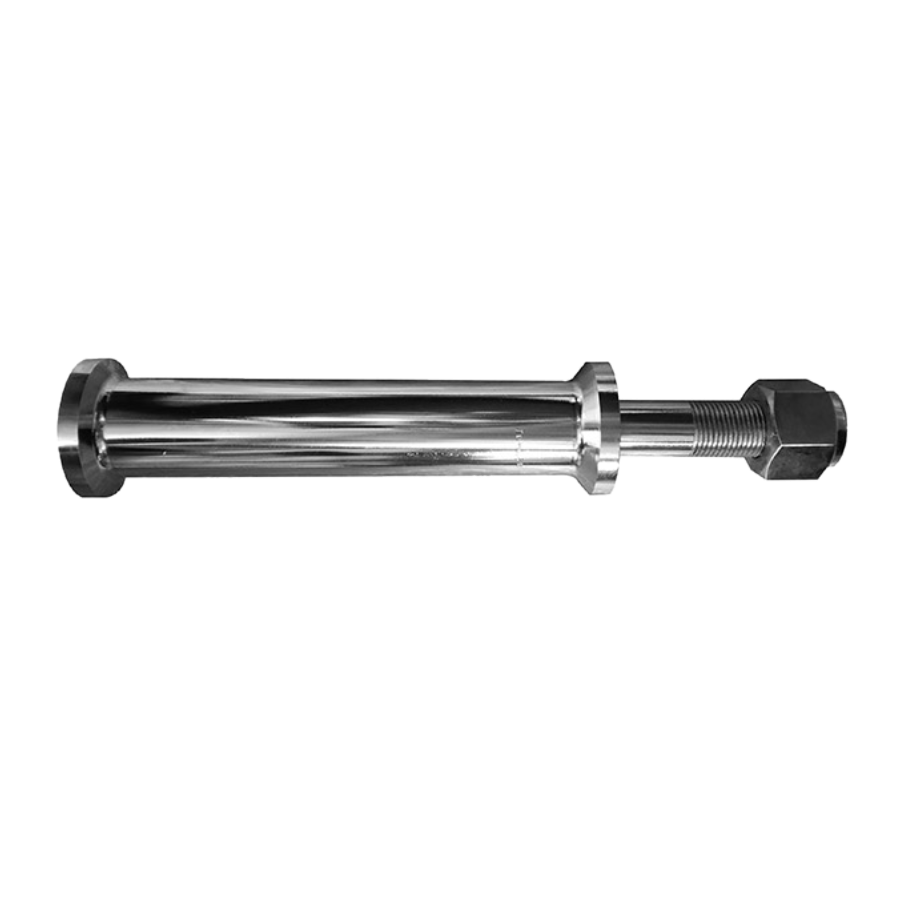

Our 35CrMo piston rod is a crucial component for oilfield mud pumps, manufactured with advanced forging techniques to ensure superior physical and chemical properties. The larger end of the piston rod is securely connected to the power end of the mud pump through a fixture, effectively transmitting power.

The smaller end fits the mud pump piston, generating stable pressure through its reciprocating motion. Treated with parkerizing, chrome plating, and nickel plating, the rod not only enhances its corrosion resistance but also improves its fatigue strength and wear resistance.

Additionally, our design minimizes deformation of the seal packing, extending the life of the seals and piston rings. Advanced roll forming technology creates a cold-hardened layer on the surface, reducing deformation of the wear surfaces and significantly enhancing durability and performance. This piston rod is meticulously designed and manufactured for the demanding environments of oil extraction, ensuring prolonged and stable operation of drilling equipment.

| Material | 35CrMo forged steel |

| Surface Treatment | Parkerizing, chrome plating, nickel plating |

| Primary Use | Designed for oilfield mud pumps |

| Features | High corrosion resistance, high density, low wear, high fatigue strength |

| Additional Components | Piston nut |

| Technological Processing | Roll forming to create a cold-hardened surface, improves fitting performance |

| Life Enhancement | Reduces deformation of seal packing, extends life of seals and piston rings |

| Performance Impact | Enhances the overall lifespan and efficiency of oilfield mud pumps |