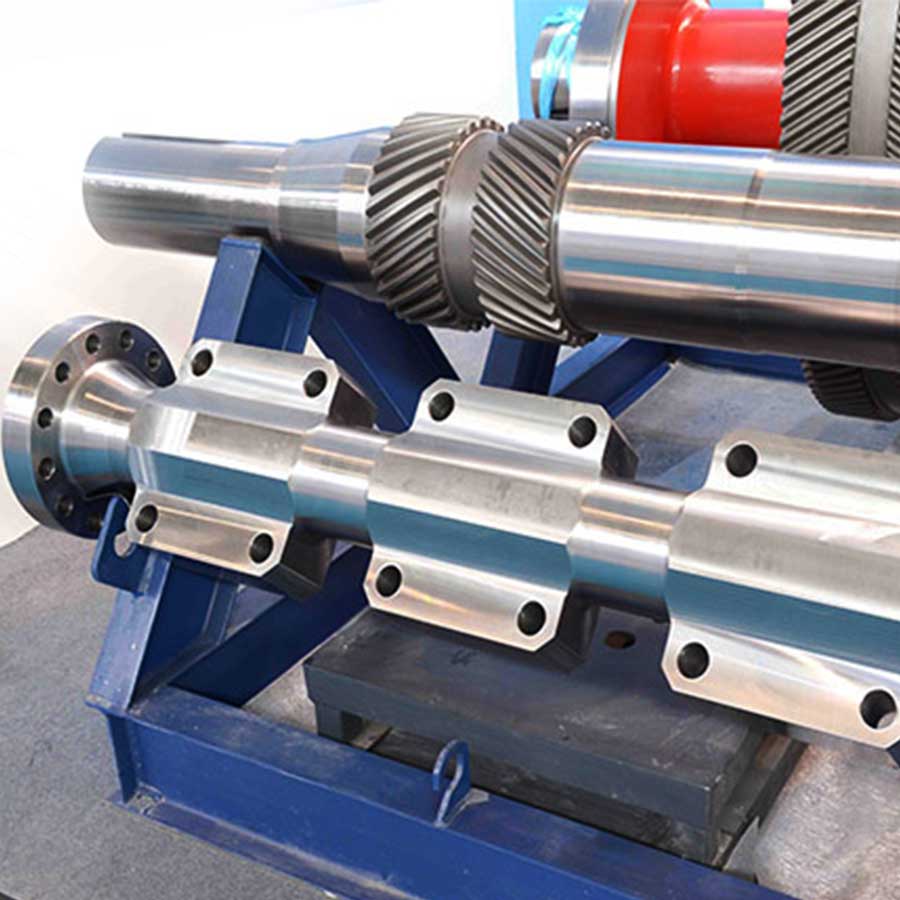

The mud pump pinion shaft assembly is a critical component in mud pumps used for oil and gas drilling. The pinion shaft is manufactured from forged alloy steel and features medium-hard helical gears that provide reliable and efficient power transmission. The assembly uses single-row radial cylindrical roller bearings with double-ribbed outer rings to facilitate easy maintenance.

The pinion shaft is made from 42CrMo steel and equipped with high-precision double helical gears. These precision gears ensure exceptionally smooth operation, minimizing noise and vibration and significantly improving power transmission efficiency. The gear’s minimal backlash ensures smooth operation without pre-wear, contributing to the longevity and reliability of the mud pump.

Specifications Table

| Parameter | Value |

|---|---|

| Material | 42CrMo Forged Alloy Steel |

| Gear Type | Double Helical Gears |

| Bearing Type | Single-row radial Cylindrical Roller Bearings with Double-Ribbed Outer Rings |

| Key Features | High Strength, Precision Machining, Minimal Noise and Vibration, Easy Maintenance |

| Function | Efficient Power Transmission, Smooth Operation |

| Application | Mud Pumps for Oil and Gas Drilling |

Applications and Role

The pinion shaft assembly is essential for efficient power transmission in mud pumps. It converts the rotational force from the drive system into the necessary motion to operate the mud pump, ensuring smooth and reliable performance. The high-precision gears and robust construction make it ideal for the demanding conditions of oil and gas drilling operations.

Key features:

- Forged Alloy Steel Construction: Ensures high strength and durability.

- High-Precision Double Helical Gears: Provide smooth and efficient power transmission.

- Minimal Noise and Vibration: Enhances operational efficiency and reliability.

- Single-Row Radial Cylindrical Roller Bearings: Simplifies maintenance with double-ribbed outer rings.

- Extended Shaft Ends: Allow for the installation of pulleys or sprockets on either end for versatile use.