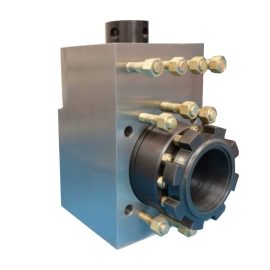

The mud pump bull gear is a key component in the power end of mud pumps, crucial for efficient power transmission in oil and gas drilling operations. Crafted from high-strength cast steel, this bull gear is engineered with helical teeth to mesh perfectly with the crankshaft, ensuring smooth and reliable operation. The inner bore of the bull gear fits tightly with the crankshaft through an interference fit, secured with bolts and lock nuts.

Advanced heat treatment techniques optimize the gear structure, enhancing its hardness and thereby improving its wear resistance and impact strength. The high-strength cast steel construction ensures the bull gear’s long-term stability and extends its operational life, even under the rigorous demands of continuous drilling.

Customization options allow for the bull gear to be tailored to specific customer requirements, including different numbers of teeth and modules, ensuring compatibility with various mud pump models. This flexibility makes it possible to integrate the bull gear seamlessly with existing pinion shafts and crankshafts, providing reliable power transmission for the mud pumps.

Specifications Table

| Parameter | Value |

|---|---|

| Material | High-Strength Cast Steel |

| Tooth Profile | Helical Teeth |

| Heat Treatment | Advanced Heat Treatment Techniques |

| Fit Type | Interference Fit |

| Connection Method | Bolts and Lock Nuts |

| Customization | Number of Teeth, Modules |

| Application | Mud Pumps for Oil and Gas Drilling |

| Key Features | High Hardness, Wear Resistance, Impact Strength, Long-Term Stability |

Applications and Role

The bull gear is essential for the power transmission system of mud pumps, converting rotational motion from the crankshaft into the necessary torque to drive the pump. Its helical tooth design ensures smooth and efficient power transfer, reducing noise and vibration during operation. The advanced heat treatment and high-strength steel construction provide exceptional durability, allowing the bull gear to withstand the harsh conditions typical in oil and gas drilling environments.