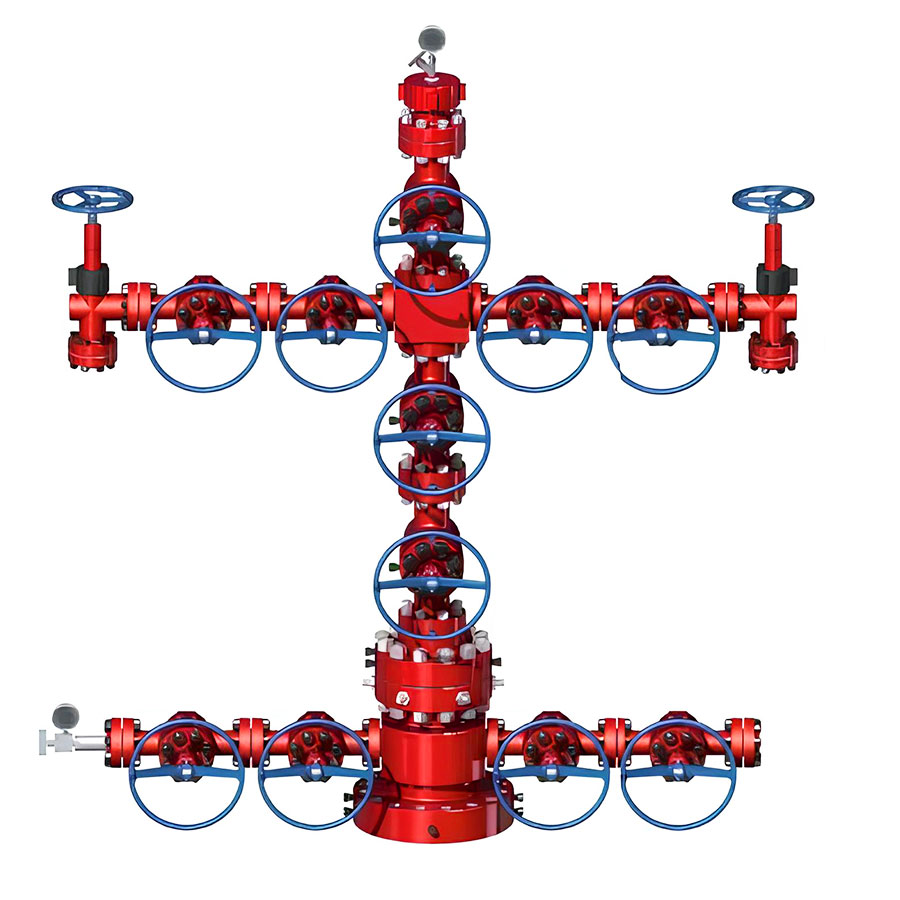

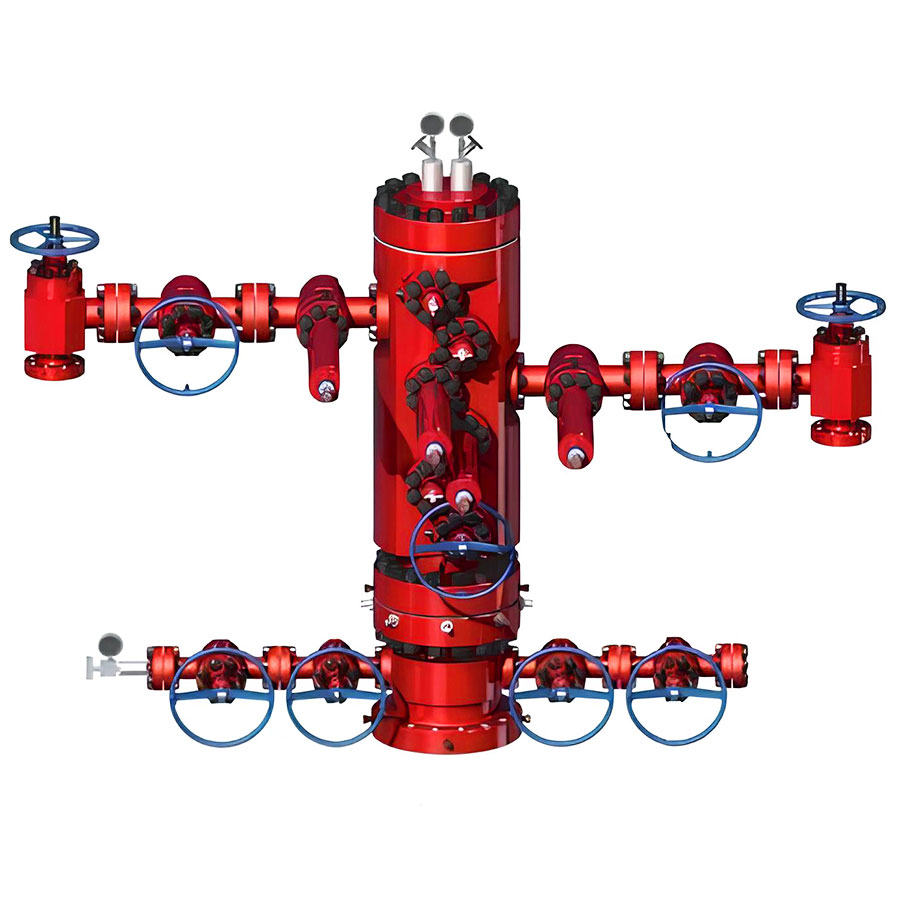

The SMKST wellhead and Christmas tree assembly is a critical component for controlling the flow of fluids from oil and gas wells. While the wellhead is primarily used during drilling operations and for riser tie-back situations, the Christmas tree is installed on top of the wellhead during production. Our assemblies are manufactured using forged or specially smelted castings, ensuring high-pressure resistance and safety. We offer a variety of configurations to meet international standards, including typical and dual-tube integrated designs. These assemblies are suitable for various media, including oil, natural gas, and other fluids, with working pressures ranging from 2,000 PSI to 20,000 PSI.

Specifications

| Parameter | Specification |

|---|---|

| Working Pressure | 2,000 PSI ~ 20,000 PSI |

| Nominal Diameter | 2 1/16″ ~ 5 1/8″ |

| Working Medium | Oil, Natural Gas, Mud, H2S, CO2 |

| Working Temperature | -46℃ ~ 121℃ (U-grade) |

| Material Grades | AA, BB, CC, DD, EE, FF |

| Standard Levels | PSL 1 ~ 4 |

| Performance Levels | PR 1 ~ 2 |

| Safety Valve Option | Pneumatic or Hydraulic Safety Valves |

Christmas Tree Benefits

The wellhead and Christmas tree assembly is crucial for fluid control in oil and gas wells. The wellhead is used during drilling operations and provides the interface for the drilling equipment. The Christmas tree is installed during production and includes various valves and fittings to control the flow of oil and gas. This assembly can be configured for various specific purposes, including oil and gas extraction, gas injection, water injection, thermal recovery, fracturing, and acidizing. The assemblies are designed for high-pressure applications, ensuring tight seals and material integrity, especially in environments containing corrosive gases like H2S and CO2.