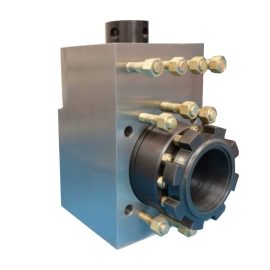

Our mud pump valve body and seat are engineered to meet API specifications and ISO9001 quality standards, crafted from high-quality alloy steel (40CrNiMo, 20CrMnTi). The components are forged and carburized, achieving a surface hardness of HRC ≥ 60. Precision CNC machining ensures perfect dimensional matching, making them ideal for both onshore and offshore platforms.

Our valve bodies and seats significantly improve operational efficiency, extending the lifespan to 4-5 times that of standard components, thereby reducing costs and workload. The valve assembly includes the valve body, seat, and inserts (rubber), with options for NBR, PU, composite PU, and HNBR materials.

Specifications Table

| Parameter | Value |

|---|---|

| Material | 40CrNiMo, 20CrMnTi |

| Standards | API, ISO9001 |

| Surface Hardness | HRC ≥ 60 |

| Manufacturing Process | Forged, Carburized, CNC Machined |

| Lifespan | 4-5 times longer than standard components |

| Application | Onshore and Offshore Platforms |

| Valve Types | Full Open Valve, Three-Valve, Four-Valve |

| Compatible Pumps | BOMCO, Honghua, National Oilwell, Emsco, Gardner Denver, Ideco, Oilwell |