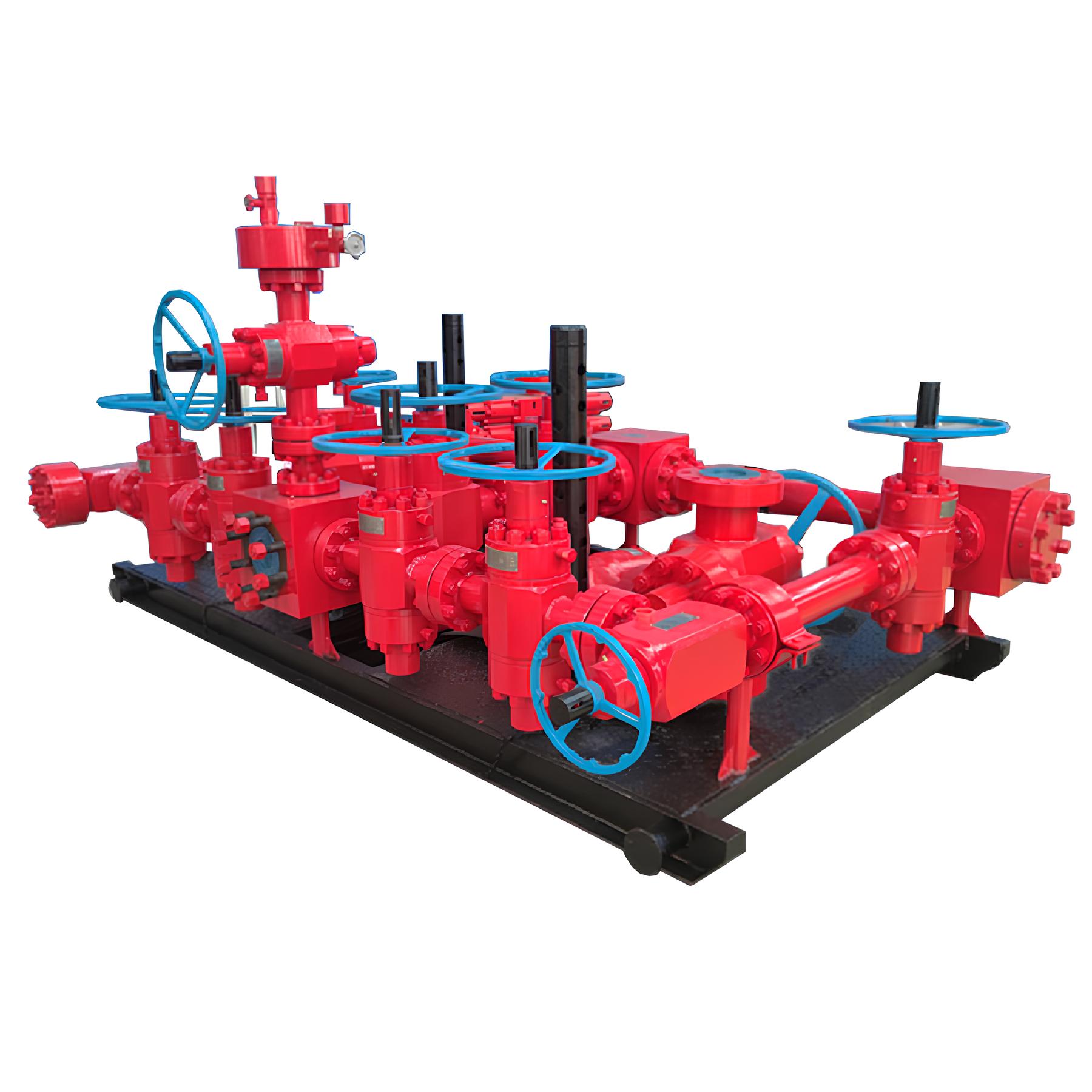

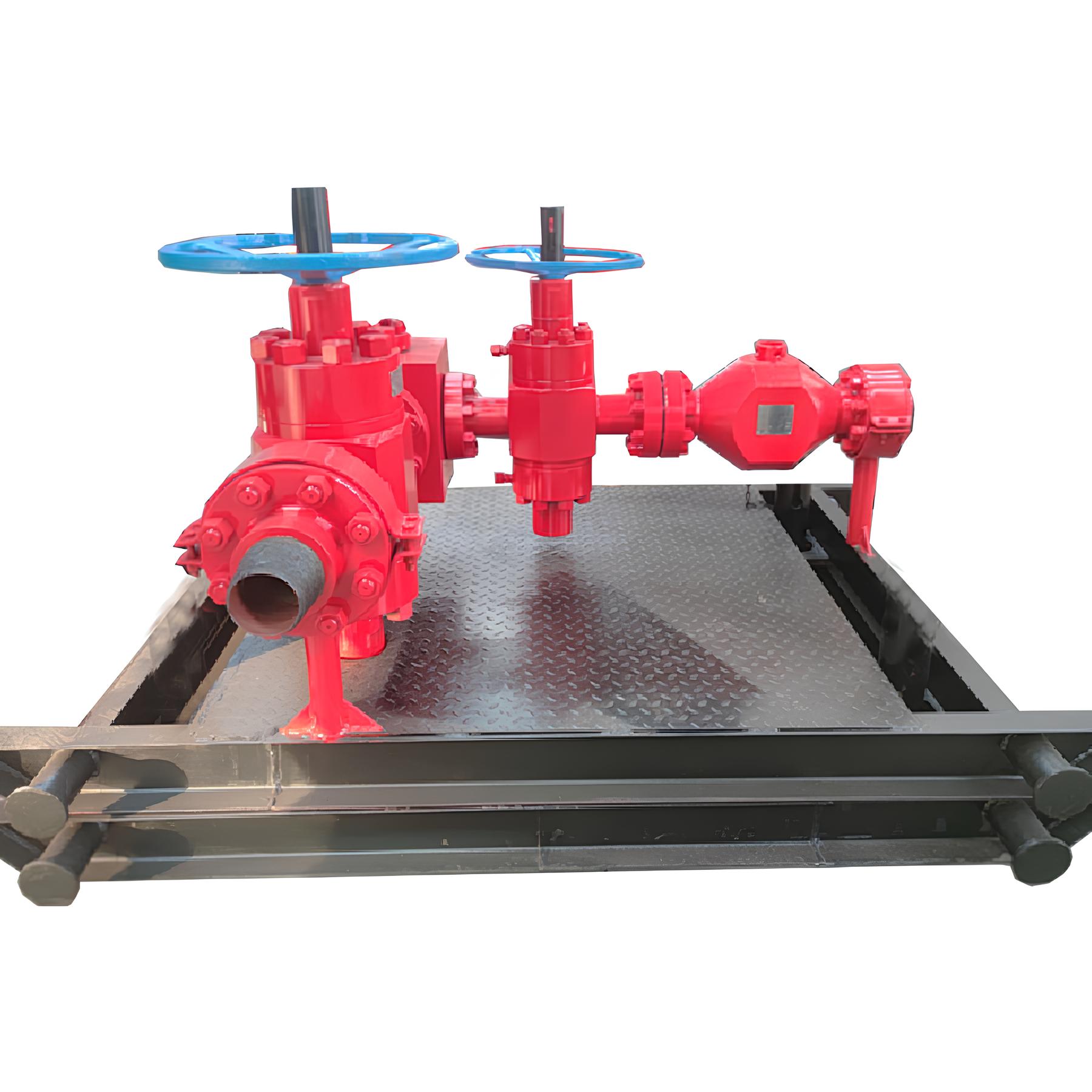

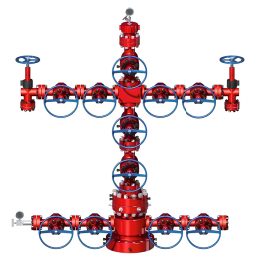

The choke and kill manifold is a critical piece of equipment in the well control system, essential for managing well influx and controlling wellbore pressure in oil and gas wells. During a kick or blowout, the choke manifold uses gate valves to modulate pressure, maintaining a stable bottom hole pressure and preventing further fluid influx. When wellbore pressure reaches critical levels, it facilitates controlled venting to protect the wellhead. The kill manifold injects drilling mud into the wellbore to balance internal pressure, aiding in well control, fire prevention, and firefighting operations.

Key Features:

- Pressure Relief via Choke Valves: Reduces wellhead casing pressure, enabling soft shut-in.

- Pressure Control: Through choke valve throttling, manages drilling process by controlling mud displacement and wellhead/stem pressures, restoring bottom hole pressure control to prevent blowouts.

- Durable Gate Valves: Full bore, bi-directional metal sealing design for extended service life.

- Structural Types: Available in lifting and standard types.

- Choke Valve Control: Options for manual or hydraulic operation (with choke control box).

- Comprehensive Components: Comprises check valves, gate valves, threaded flanges, and pressure gauges.

- Enhanced Safety: Supports well control, fire prevention, and firefighting assistance through effective pressure management.

SMKST provides a variety of choke and kill manifolds that meet international standards for drilling operations, along with compatible accessories and other petroleum machinery.