SMKST Ceramic Liners are built for drilling environments where wear resistance, chemical durability, and extended liner life are critical. Made from zirconia-alumina composites, these liners exceed expectations in HTHP wells and abrasive mud conditions. With a service life of over 2000 to 4000 hours, they minimize downtime and cut operating costs — all while delivering consistent performance up to 7500 psi and 350°F.

Specifications

| Parameter | Ceramic Liners |

|---|---|

| Material | Zirconia-based Ceramic + AISI 1045 steel |

| Hardness | HRC > 90 |

| Service Life | 2000–4000+ hours |

| Max Operating Pressure | 7500 psi (52 MPa) |

| Operating Temperature | 20–350°F (–6.7 to 176.7°C) |

| pH Range | 2–14 |

| Applications | Oil & gas drilling, HTHP wells, abrasive muds |

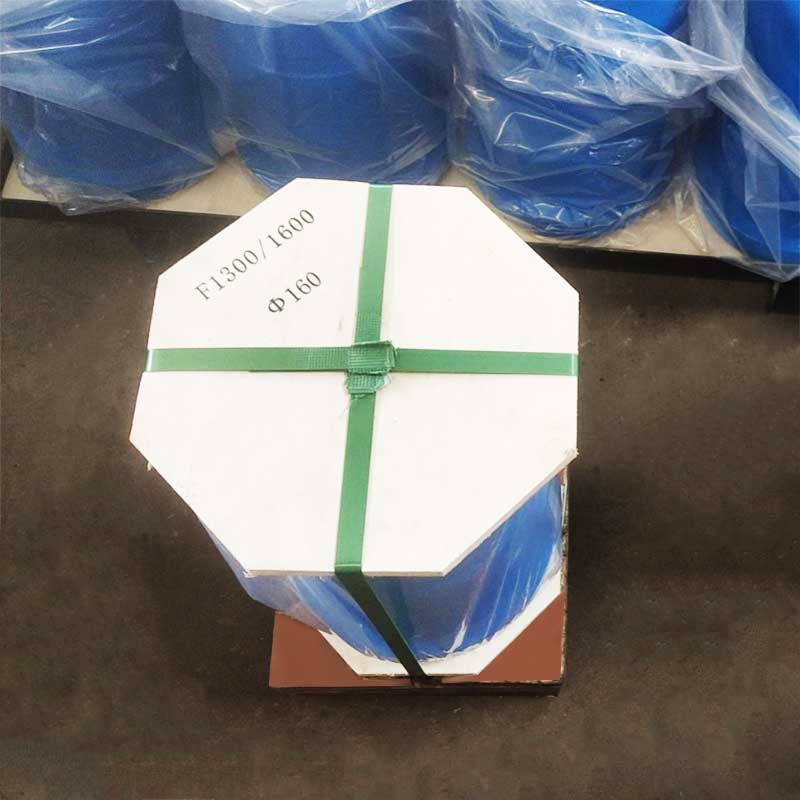

| Compatible Pumps | F-series, 3NB, PZ, UNBT, UBT, and others |

| Customization | Available per client drawing |

Material Advantage

We use a unique material blend:

- Zirconia (ZrO₂) stabilized with 5.4% Yttria – improves toughness

- 99.9% Alumina – boosts wear resistance

- Fine-grain sintering ensures high density and a smooth finish for better sealing and piston life

Contact us to explore how SMKST ceramic liners can optimize your drilling operations with enhanced durability and performance.

Why Choose SMKST?

- Chengdu-based Manufacturing: Center of global land rig production

- Large Inventory & Fast Shipping: Global coverage, daily dispatch

- Lower Cost, Same Quality: Competitive vs Western products

- Custom Fit Available: Match your liner spec with drawings

- 20+ Years in Oilfield Supply: Trusted by contractors worldwide

All SMKST ceramic and bi-metal liners meet or exceed API standards.

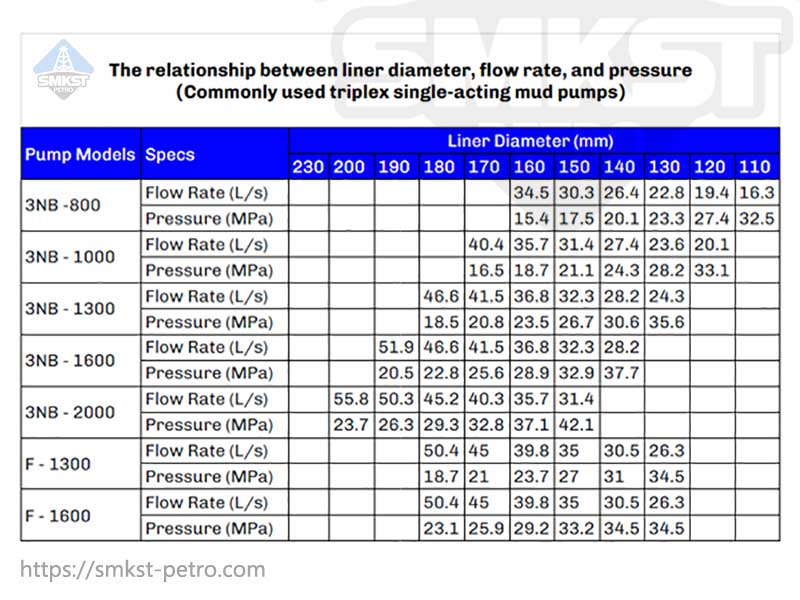

Mud Pump Liner Pressure Ratings Table

To ensure compatibility and optimal performance, SMKST mud pump liners are rated for various pressure levels tailored to meet the demands of different drilling operations.