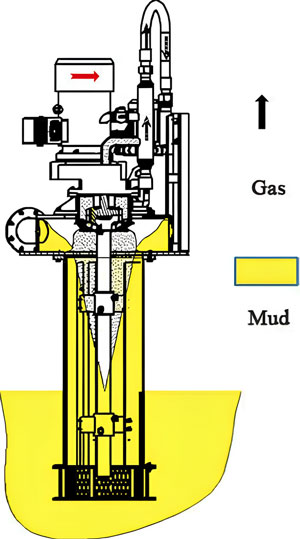

The centrifugal degasser offered by SMKST is an essential component of oil rig solids control equipment, primarily used for processing drilling fluids. It boasts high treatment capacity, excellent gas removal efficiency, compact footprint, and ease of use and maintenance. The filters and impellers are welded from stainless steel, providing high corrosion resistance. Additionally, the unit is coated with heavy-duty anti-corrosion paint, significantly extending its service life.

Centrifugal Degasser Specifications

| Model | SMKST-CD300 |

|---|---|

| Liquid Inlet Nominal Diameter | 20″ |

| Liquid Outlet Nominal Diameter | 8″ |

| Gas Outlet Nominal Diameter | 2″ |

| Maximum Throughput | 300 m³/h |

| Maximum Gas Removal Rate | 30 m³/h |

| Main Motor Power | 22 kW |

| Fan Power | 2.2 kW |

| Weight | 1375 kg |

| Dimensions (L×W×H) | 1150×1055×2885 mm |

The Benefits of Centrifugal Degasser

A centrifugal degasser is a new type of degassing equipment designed for handling gas-invaded drilling fluids. It is typically installed after the shale shaker. Suitable for all types of mud purification systems, it plays a crucial role in restoring mud density, stabilizing mud viscosity, and reducing drilling costs. It can also serve as a high-power agitator. The advantages of the centrifugal degasser include high processing capacity, high degassing efficiency, small footprint, low energy consumption, and easy use and maintenance.