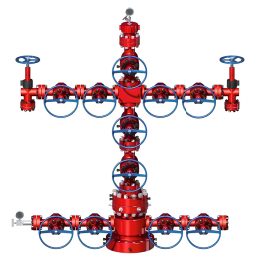

Well Control Equips

Well control equipment for preventing uncontrolled releases of formation fluids (oil, gas, water) and potential blowouts. We offers: Blowout Preventers (BOPs), Choke Manifold, Safety Valves, Choke Manifold, Kill Line, etc.

by-SMKST-270x270.webp)

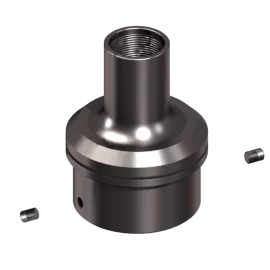

| Product Name | Back Pressure Valve (BPV) |

|---|---|

| Working Pressure | 2,000 psi – 20,000 psi |

| Applications | Christmas Tree Installation, Wellhead Assembly, Pressure Test |

| Size Range | 1 1/4″ – 6 5/16″ |

| Material Class | DD, EE, FF |

| Sizes | 2", 2-1/2", 3", 3-1/2" |

|---|---|

| Working Pressure | 2,000 psi to 15,000 psi |

| Operation Types | Options for both pressurized and non-pressurized deployment |

| Application | Oil, gas, geothermal drilling, well intervention, underbalanced drilling |

|---|---|

| Standards | API 16A and GB/T20174 |

| Pressure Rating | 500psi ~ 20,000psi |

| Nominal Diameter | 2 9/16” ~ 30” |

| Standard | API 6B or API 6BX |

|---|---|

| Category | Oil and gas wellhead equipment |

| Bottom Connections | Threaded, welded, or slip-type |

| Side Outlets | Pipeline thread or studded |

| Material | AISI 4140 Alloy Steel |

|---|---|

| Standard | API Spec 6A, NACE MR0175 |

| Function | Pressure Testing, Wear Bushing Installation and Retrieval |

| Working Pressure | 2,000 PSI – 20,000 PSI |

| Pressure | 2000 PSI – 15000 PSI |

|---|---|

| Standards | API Spec 6A, NACE MR0175 |

| Application | Wellhead Assembly, Christmas Tree Installation |

| Sizes | 7-1/16", 11", 13-5/8", 20-3/4", 21-1/4", or customized |

|---|---|

| Working Pressure | 2,000 PSI – 20,000 PSI |

| Material | AISI 4130 Alloy Steel, or as per customer request |

| Standards | API Spec 6A, API Q1, NACE MR0175 |

| Material Class | AA, BB, CC, DD, EE, FF |

Categories

- Drill Bits (5)

- Drilling Rig (11)

- Skid-Mounted Rig (9)

- Mud Pump (6)

- Mud Pump Parts (22)

- MWD Tools (2)

- Rig Floor Equips (22)

- Shale Shaker Screens (15)

- Solid Control Equips (11)

- Used Oil Drilling Rigs (4)

- Well Control Equips (12)