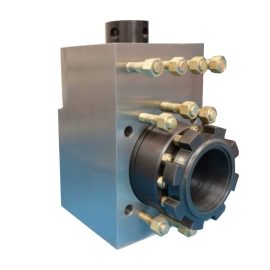

The mud pump pulsation dampener is vital for mud pumps in oil and gas drilling operations, reducing pressure and flow fluctuations to enhance suction efficiency. Installed on discharge lines, our dampeners feature advanced bladder technology, making them ideal for high-pressure oil and chemical pipelines. They also serve as stabilizers and shock absorbers in air extraction systems, ensuring smooth and safe operation.

Features

- Reduces Pressure Fluctuations: Balances peak pressures for smoother pump operation.

- Increases Water Horsepower: Enhances overall pump efficiency and performance.

- Minimizes Wellbore Leakage: Reduces the risk of fluid losses in the wellbore, ensuring operational integrity.

Types

- Discharge Pulsation Dampener: Reduces pressure and flow fluctuations in pump discharge.

- Suction Dampener: Improves suction conditions to prevent cavitation and ensure steady flow.

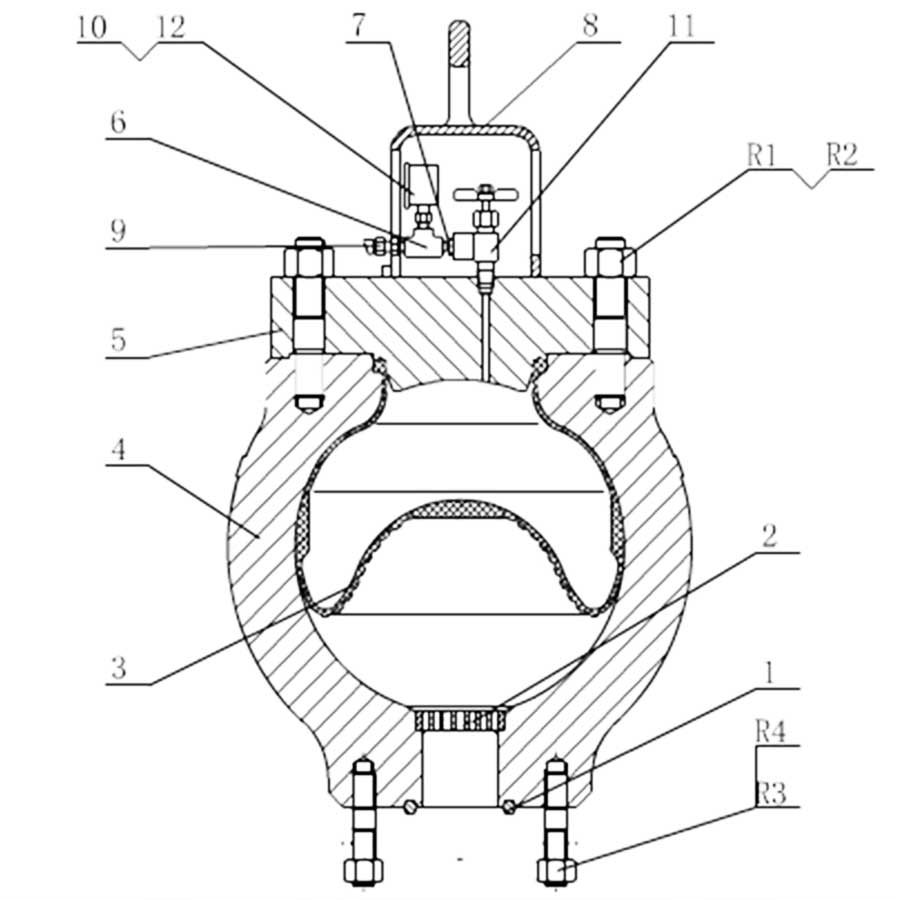

Structure

The pulsation dampener consists of:

- Dampener Housing

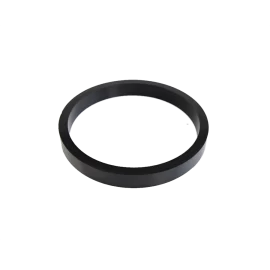

- Bladder

- Plate

- Pressure Gauge

- Shut-off Valve

Working Principles

- Discharge Buffer: Positioned at pump and compressor discharge ends, it prevents damage to cylinder pistons, valves, seats, and pipelines due to pressure fluctuations, extending equipment lifespan.

- Oscillation Absorption: Absorbs shock pressure from valve closures in fluid systems, preventing water hammer effects that can damage pipes and downstream equipment.

- Reverse Oscillation: Mitigates reverse oscillation caused by fluid impacts on pump valves, preventing sudden pump shutdowns.

- Energy Storage: The unique design allows energy storage in hydraulic systems, providing a short-term energy supply as needed. This is crucial for maintaining lubrication in critical rotary sprayers, preventing costly equipment failures.

Specifications Table

| Parameter | Value |

|---|---|

| Material | High-Quality Bladder |

| Surface Treatment | Nickel Plating |

| Application | Mud Pumps for Oil and Gas Drilling |

| Key Features | Reduces Pressure Fluctuations, Increases Water Horsepower, Minimizes Wellbore Leakage |

| Function | Balances Peak Pressure, Stabilizes Pressure, Reduces Losses |

| Installation Location | Discharge and Suction Lines |

| Pressure Resistance | High |

| Corrosion Resistance | High |

Role of Pulsation Dampeners

Pulsation dampeners act as protective barriers in pumps, reducing the impact of pressure fluctuations and ensuring stable operation. They balance peak pressures, stabilize flow, and protect equipment from damage caused by pressure surges. Reducing friction and evenly distributing loads enhance the pump’s lifespan and performance.

In summary, pulsation dampeners are crucial for reducing pressure fluctuations, protecting equipment, and ensuring efficient operation of mud pumps in demanding oil and gas drilling environments.