SMKST provides high-quality mud pump liners, including ceramic liners and steel liners, for land drilling rigs around the world. Built to handle high pressure, heat, and abrasive drilling fluids, with strong wear resistance and long service life, they help reduce pump failures and maintenance time. Based in Chengdu, China — one of the largest drilling equipment hubs globally — we benefit from a wide local supply chain and lower production costs. This allows us to offer competitive pricing without compromising on quality. With over 20 years of global oilfield supply experience and a large inventory, SMKST ensures fast delivery and stable support for your drilling projects.

Mud Pump Liners Specification

| Feature | Ceramic Liners | Bi-metal Liners |

| Material | Zirconia-based ceramic + AISI 1045 steel | Hardened or chrome-plated AISI 1045 steel |

| Hardness | HRC 92–94 | HRC 58–69 |

| Service Life | 2000–4000 hours | ~800 hours |

| Max Operating Pressure | 7500 psi | 7500 psi |

| Temperature Range | 20–350°F (–6 to 177°C) | 20–240°F (–6 to 115°C) |

| Corrosion Resistance | Excellent | Moderate |

| Wear Resistance | Excellent | Good |

| Best For | Long runs, high-temp, abrasive muds | Standard drilling, budget-focused operations |

| Cost | Higher upfront, lower long-term cost | Lower upfront, more frequent replacement needed |

Wide Compatibility with Major Mud Pump Brands

SMKST supplies mud pump liners that fit a wide range of models and brands. We understand that each pump has its own structure and size. That’s why our liners come in multiple configurations to ensure a precise fit, whether for standard rigs or customised equipment. We offer liners compatible with many leading mud pump series, including but not limited to:

- Bomco: F-500, F-800, F-1000, F-1300, F-1600, F-1600HL

- Brewster: B-1000-T, B-1100-T, B-1300-T, B-1600-T

- HONGHUA: HHF-500 to HHF-2200HL

- Other: Emsco, National, Oilwell, Ideco, Gardner Denver, Wirth, Drillmec, Russian pumps, Upetrom, and more.

Need a custom size? Just send us your technical drawings—we can produce liners to match special or non-standard pump setups.

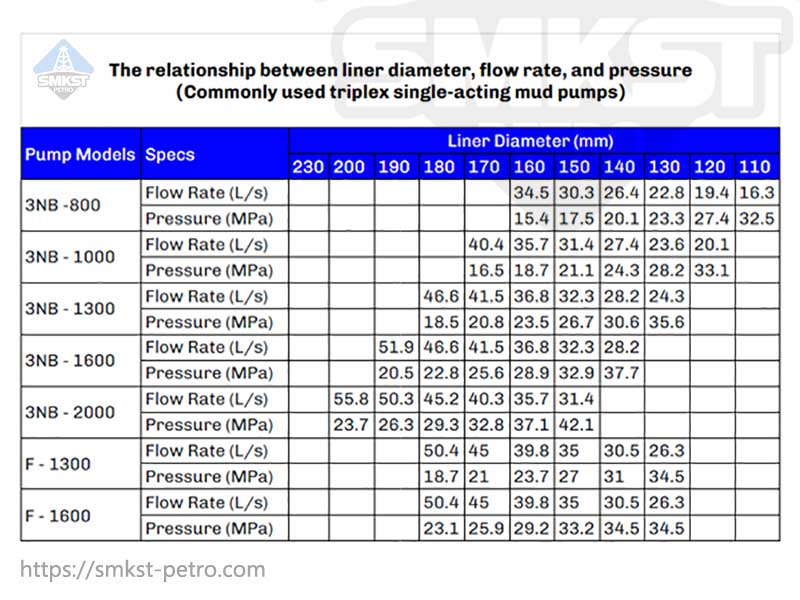

Mud Pump Liner Pressure Ratings Table

To ensure compatibility and optimal performance, SMKST mud pump liners are rated for various pressure levels tailored to meet the demands of different drilling operations.

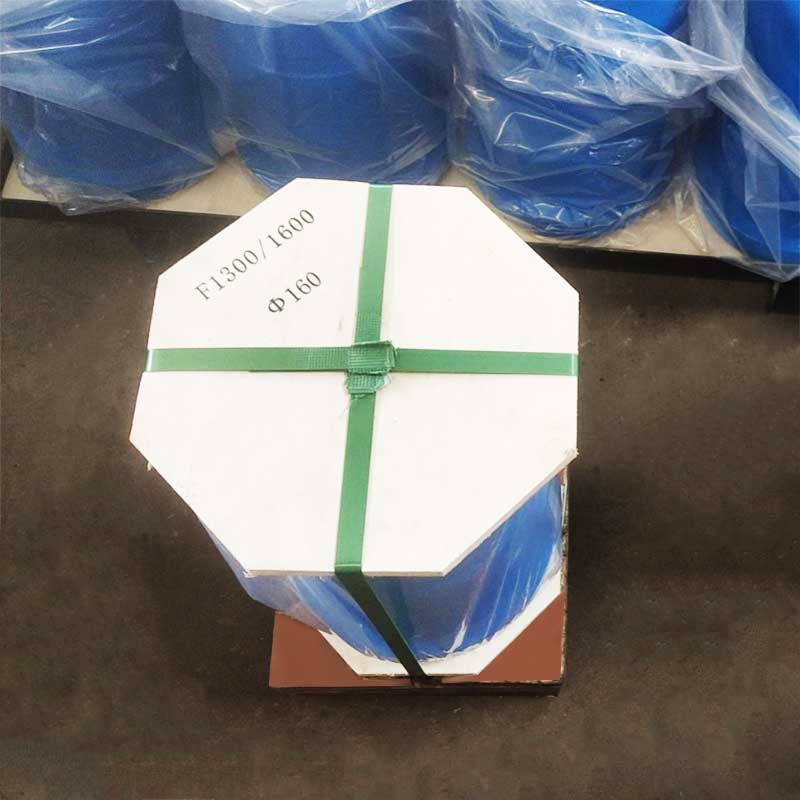

Mud Pump Liners Gallery