On many drilling rigs—especially offshore platforms or compact land-based sites—space is a critical constraint. Traditional solids control systems often require multiple standalone units like desanders and desilters, each occupying a separate footprint. This scattered setup can significantly limit available rig space and complicate layout planning.

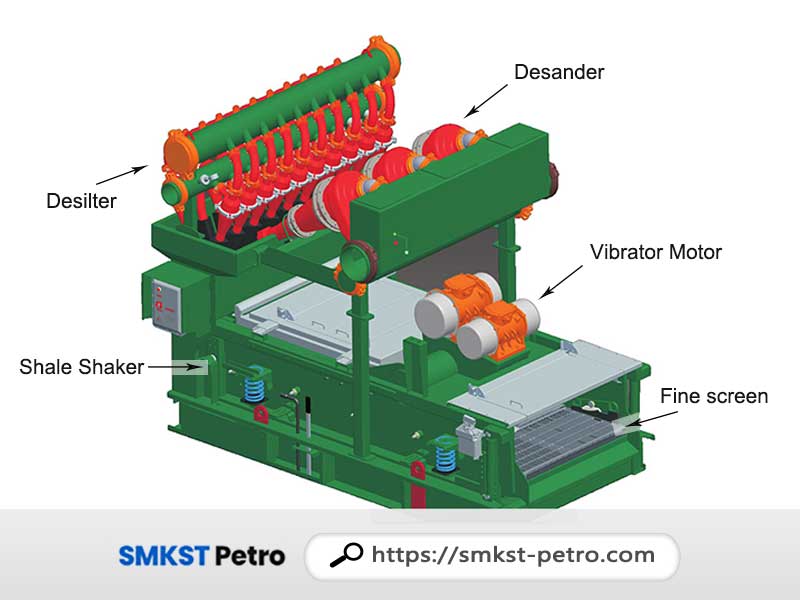

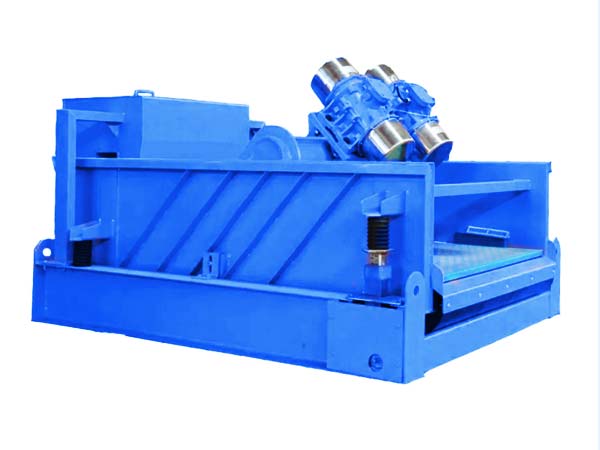

To address this challenge, the mud cleaner offers a smart, space-saving solution. By mounting desander and/or desilter hydrocyclones directly above a fine-mesh shaker screen, this integrated system delivers two-stage solids separation in a single compact unit. Compared to installing separate machines, this combination dramatically reduces the overall space requirement, making it an ideal choice for high-density rig environments where every square foot counts.

But space efficiency isn’t the only advantage. In this article, SMKST provides a practical, field-tested guide to how mud cleaners work, their key components and benefits, and important selection criteria. Whether you’re a mud engineer, solids control specialist, or drilling supervisor, you’ll find actionable insights on how to apply mud cleaners effectively—and how well-designed equipment can improve drilling efficiency while reducing overall fluid treatment costs.

Mud Cleaner Explained: Structure, Principle, and Key Advantages

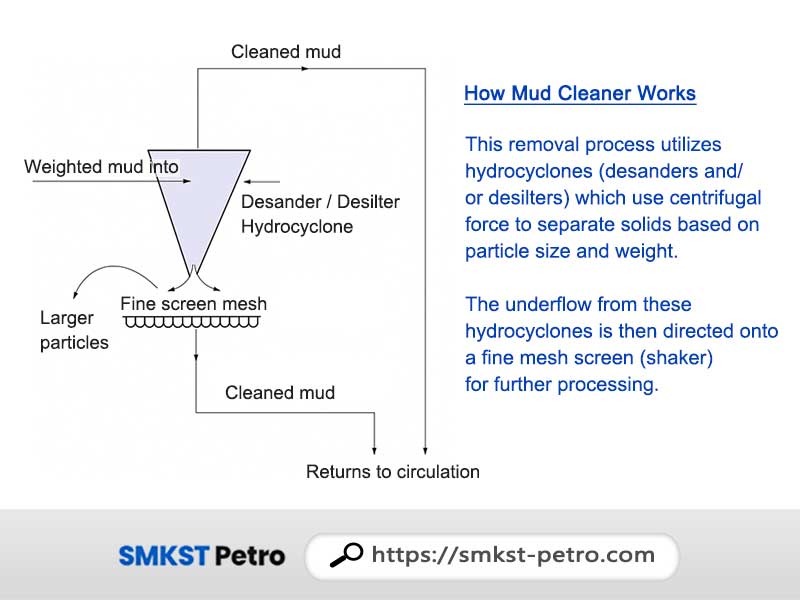

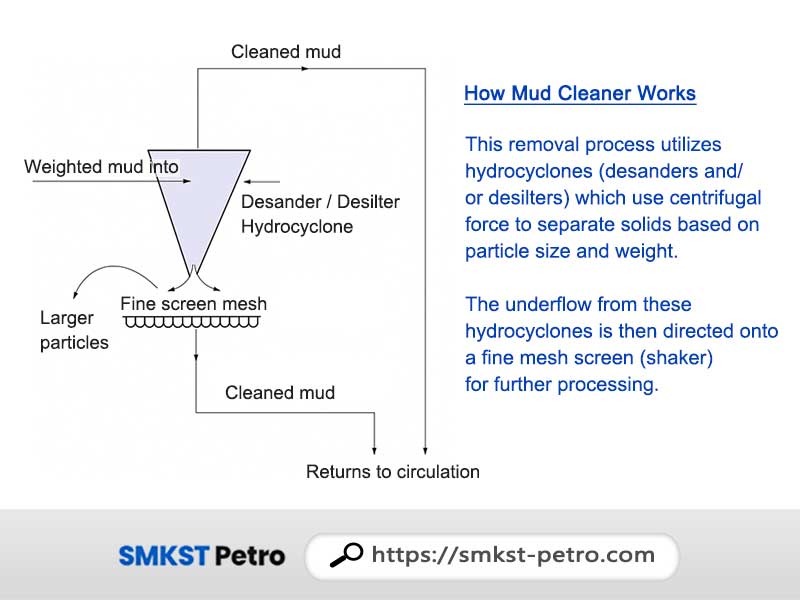

A mud cleaner is a compact, integrated solids control device that combines desander and/or desilter hydrocyclones with a fine-mesh shaker screen. It is specifically designed to bridge the gap between the primary shale shaker and downstream centrifuges, handling the mid-size particles that neither can efficiently manage alone. In a single two-stage unit, the mud cleaner applies centrifugal separation followed by vibratory screening, offering more precise solid–liquid separation and improved mud recovery.

Compared to using standalone desanders and desilters, a mud cleaner provides several critical advantages:

1. Removes Fine Solids Missed by Traditional Shakers

Primary shale shakers typically remove solids larger than 74 μm (sometimes over 100 μm), while standalone desanders handle particles around 45–74 μm, and desilters target the 15–44 μm range. A mud cleaner, by integrating both hydrocyclones and a fine screen, is optimized to process particles between 15–74 μm, precisely the range that escapes the primary shaker. This improves overall solids control efficiency and reduces the accumulation of fine, damaging solids in the active mud system.

2. Recovers Valuable Drilling Fluid from Underflow

Hydrocyclones alone discharge underflow that contains not only unwanted solids, but also a significant volume of useful drilling fluid. Without further treatment, this results in unnecessary mud loss. The mud cleaner’s key innovation lies in placing the shaker screen directly beneath the hydrocyclones. This allows the underflow to be immediately screened and dewatered, recovering much of the fluid that would otherwise be discarded with the cuttings.

3. Improves Mud Recovery and Cuttings Dryness

The fine screen beneath the cones effectively separates reusable fluid from solids, producing drier discharge and improving the fluid recovery ratio. This reduces the need for mud dilution, lowers disposal costs, and minimizes the environmental footprint—all while maximizing the economic value of each barrel of drilling fluid.

4. Saves Space and Simplifies Rig Layout

By integrating desanding, desilting, and screening functions into one compact unit, the mud cleaner significantly reduces the overall equipment footprint. This is particularly valuable on offshore platforms and compact land rigs where space is at a premium. Compared to scattered equipment layouts, a mud cleaner allows for tighter, more efficient rig-up configurations without compromising performance.

How to Choose the Right Mud Cleaner

Selecting the right mud cleaner involves more than just picking a size or flow rate—it requires matching the equipment’s design to your rig’s specific drilling conditions, mud properties, and operational goals. Below are several key factors to consider when evaluating and selecting a mud cleaner:

1. Processing Capacity and Cone Configuration

The processing capacity of a mud cleaner is primarily dictated by the number and size of its hydrocyclones. Industry-standard values show that a 10-inch desander cone typically handles around 500 GPM (≈1900 L/min), while a 4-inch desilter cone processes approximately 60 GPM (≈230 L/min) under normal operating pressure. The total capacity of the unit depends on how many cones are installed in parallel and whether both desander and desilter stages are included.

When selecting a mud cleaner, it’s essential to match the system’s overall throughput with the expected circulating volume of your well. In high-volume drilling operations, under-sizing the cyclone array can lead to system overload, reduced separation efficiency, and fluid bypass. Proper configuration ensures that the hydrocyclones can effectively remove unwanted solids without overburdening the shaker deck below, maintaining consistent performance even under heavy solids loading.

Hydrocyclone Capacities – SMKST Mud Cleaner Reference Data

| Component | Specification |

| Desander Cyclone Diameter | 10″, 12″ |

| Desilter Cyclone Diameter | 4″ |

| 10″ Cone Capacity | 115 m³/h (≈ 1900 L/min, 500 GPM) |

| 12″ Cone Capacity | 130 m³/h (≈ 2167 L/min, 572 GPM) |

| 4″ Cone Capacity | 14 m³/h (≈ 233 L/min, 62 GPM) |

| Rated Pressure | 0.23 MPa |

| Cyclone Material | High-temp resistant polyurethane |

Note: These figures are based on standard operating conditions and may vary with mud type, pressure, and solids concentration.

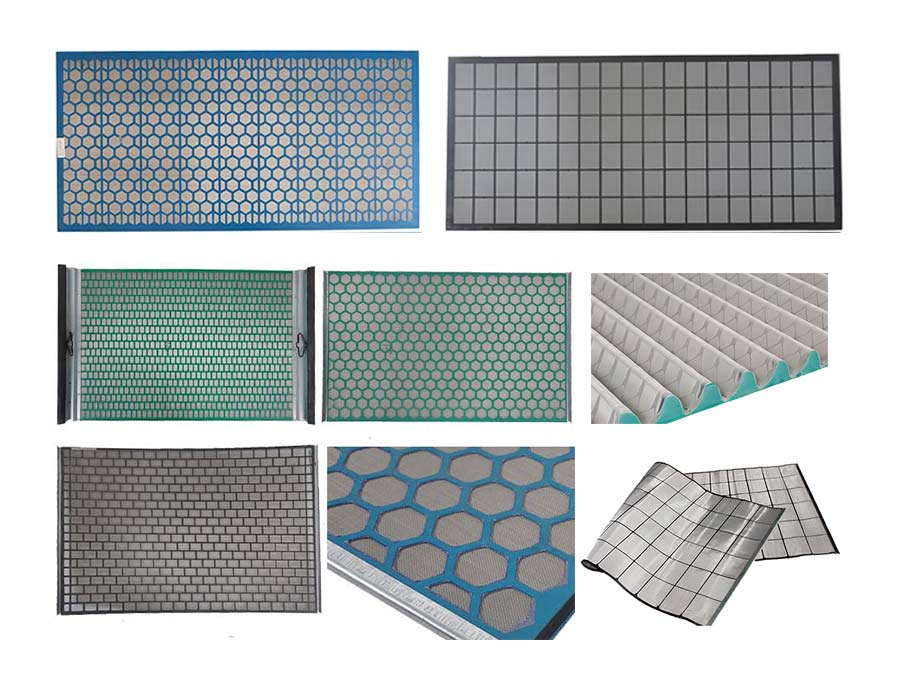

2. Shaker Screen Selection (Mesh and Area)

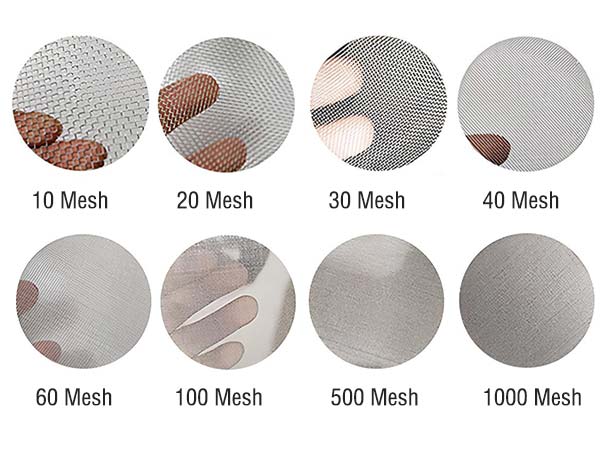

While hydrocyclones handle bulk separation, the shaker screen beneath them determines how precisely fine solids are removed. This performance is defined by the screen’s API rating, based on the API RP 13C standard.

For example, an API 100 screen removes particles between 137 and 165 μm, while API 140 and API 200 go finer, targeting ranges down to 98–116 μm and 69–82 μm, respectively. Most mud cleaners use screens rated from API 100 to API 325, with API 150 being a typical default. The choice of API rating depends on formation type, solids concentration, and the need to retain barite while maximizing fluid recovery.

Related Reading: A Deep Dive into Shale Shaker Screen Size

In addition to cut-point precision, the screen’s physical design also affects performance and durability. Options include pre-tensioned or hook-strip styles, flat or pyramid profiles, and composite or steel frames. Pyramid and composite screens generally offer more screen area and longer service life, while steel-frame screens may provide better rigidity under heavy loads. Selecting the right combination of API rating and screen structure ensures efficient separation with minimal downtime and optimal cost control.

3. Mud Properties and Solids Loading

The type of drilling fluid and the level of solids loading play a critical role in mud cleaner performance. In high-solids or weighted mud systems, where the slurry is dense and abrasive, the equipment must be robust enough to prevent issues like screen blinding or cone choking. This requires careful selection of cone size, screen mesh, and motor vibration strength to ensure stable operation without frequent shutdowns.

For non-aqueous fluids (NAF) such as oil-based or synthetic-based muds, the cleaner must be built with chemically resistant materials and enhanced sealing systems. These fluids tend to be more corrosive and have different flow characteristics, which can increase the risk of leaks or premature wear if the system is not properly configured. Using abrasion-resistant polyurethane cones, corrosion-proof screen frames, and proper elastomer sealing can significantly improve service life and maintain fluid integrity.

4. Vibration Mode and Motor Configuration

The vibration system of the underflow shaker plays a crucial role in the mud cleaner’s overall performance, especially in terms of cuttings dryness, fluid recovery, and screen longevity. The two most common motion types are linear and balanced elliptical. Linear motion provides high G-force and strong forward conveyance, making it ideal for handling high-solids drilling fluids where aggressive separation is needed. In contrast, balanced elliptical motion is gentler on screens and works better with sticky, fine, or low-density cuttings, helping to reduce blinding and screen wear in sensitive formations.

When selecting a mud cleaner, it’s also important to consider the motor configuration and control system. Explosion-proof motors are essential for rigs operating in hazardous zones, and the choice between fixed-speed drives and variable frequency drives (VFDs) can impact how precisely vibration intensity is adjusted in real-time. A VFD system offers more operational flexibility, allowing the vibration to be tuned to match fluid properties and solids loading throughout the drilling cycle.

5. Safety and Compliance Standards

In drilling environments with flammable gases, high pressures, or offshore constraints, compliance with safety and performance standards is not optional—it’s essential. Mud cleaners used in such zones must meet electrical safety certifications such as ATEX or IECEx, which regulate equipment operation in explosive atmospheres. These standards ensure that motors, wiring, and control enclosures are properly sealed and rated to prevent ignition risks.

Beyond electrical safety, screen modules should conform to API RP 13C, which defines performance metrics like D100 cut-point and conductance. This ensures consistent, measurable screen performance across manufacturers and operating conditions. Mud cleaners built to these standards offer greater operational transparency, easier cross-vendor compatibility, and a clear baseline for field performance expectations.

6. Integration with Existing Solids Control Systems

Beyond performance specs, a mud cleaner must fit seamlessly into your rig’s existing solids control layout. This includes matching the flow direction and elevation with upstream and downstream equipment to maintain consistent fluid dynamics and avoid backflow or pooling. A well-integrated unit reduces bottlenecks and minimizes unnecessary piping adjustments during installation.

It’s also important to evaluate the physical footprint and frame design. Mud cleaners with modular, skid-mounted structures are easier to transport and install, especially in compact land sites. Lastly, compatibility with your existing screen inventory can simplify maintenance logistics. Choosing a unit that accepts the same screen sizes or mesh types already in use can significantly reduce downtime and spare parts complexity.

Conclusion

A well-selected mud cleaner doesn’t operate in isolation—it must fit seamlessly into the broader solids control system, both in design and in function. As discussed, performance depends on the right match of cone capacity, screen rating, motion system, and material durability, all shaped by your mud type, flow rate, and rig layout.

Once technical needs are clarified, other practical questions naturally follow, such as how suppliers differ in lead times, customization options, or screen compatibility. If you’re exploring suppliers for your next solids control upgrade, SMKST offers field-tested mud cleaners with a balance of performance, configurability, and support. We’re familiar with the operational demands of both land and offshore rigs and can help evaluate whether a given configuration is a fit for your mud control system.

Hi, kam dashur të di çmimin tuaj

Hola, volia saber el seu preu.

Hej, jeg ønskede at kende din pris.