Updated on: May 21, 2025

When it comes to oil drilling, mud pumps play a pivotal role in maintaining the flow of drilling fluids, often described as the “blood” of the operation. At the heart of these pumps lies the liner, a crucial component that determines the pump’s efficiency, longevity, and ability to withstand demanding conditions. Selecting the right liner is not just a technical decision but a strategic one that directly impacts drilling performance and cost-effectiveness.

In the following sections, we’ll explore the main categories of mud pump liners, their applications, and practical tips for making the right choice. (Reviewed by the drilling engineering team at SMKST Petro. For reliable mud pump liners sourcing from China, get in touch with SMKST — your trusted supply partner.)

Understanding the Types of Mud Pump Liners

Mud pump liners can be broadly categorized by their material composition, compatibility with specific pump series, and available sizes. Each type offers distinct advantages and is suited for particular drilling environments. Understanding these categories is essential for making informed decisions.

1. Material-Based Categories

To increase the lifespan of mud pump liners, engineers and manufacturers have continuously refined their designs and materials. Historically, the need for more durable liners arose from the challenges of high-pressure drilling and abrasive mud compositions. Below, we explore the three main types of mud pump liners based on material.

1) Single-Metal Liners

Single-metal liners were the first major innovation in mud pump design. Made from high-carbon or alloy steel, these liners undergo surface hardening treatments, such as carburizing or nitriding, to enhance their resistance to wear and tear. While they offer a cost-effective solution for low-demand operations, their relatively short lifespan of 50 to 200 hours makes them less suitable for intensive drilling projects.

2) Bi-Metal Liners

To overcome the limitations of single-metal liners, bi-metal liners were developed. These liners combine a carbon steel outer shell with a high-chromium iron inner sleeve, offering enhanced wear resistance and corrosion protection. The production process involves precise centrifugal casting to ensure a durable bond between the two materials, resulting in a liner that can endure 300 to 800 hours of operation.

3) Ceramic Liners

For extreme drilling conditions, ceramic liners represent the cutting edge of material science. Manufactured using advanced zirconia and alumina composites, these liners offer unparalleled resistance to abrasion, corrosion, and extreme pressures. Their lifespan, which typically exceeds 2,000 hours, positions them as the top choice for deepwater drilling, ultra-deep wells, and other high-stakes operations.

Despite their exceptional durability, ceramic liners come with a higher cost and require careful handling to prevent cracking or damage.

4) Comparison Table

| Feature | Single-Metal Liners | Bi-Metal Liners | Ceramic Liners |

| Material Composition | High-carbon or alloy steel | Carbon steel + high-chromium iron | Zirconia and alumina composites |

| Lifespan | 50–200 hours | 300–800 hours | 2,000+ hours |

| Cost | Low | Low | High |

| Hardness | HRC 55–65 | HRC 60+ | HRC 90+ |

2. Pump Series Compatibility

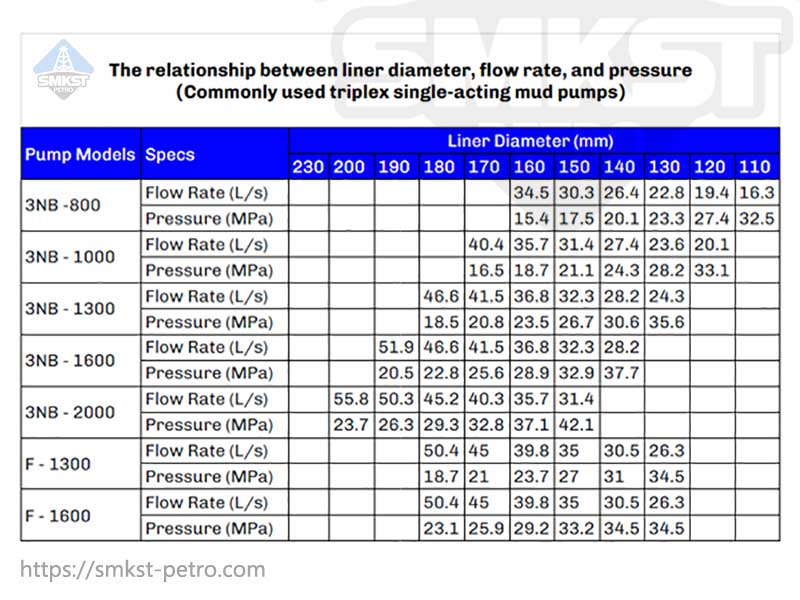

In addition to material differences, liners are also categorized by their compatibility with specific mud pump models like F-series, 3NB-serie, PZ, UBT, and UNBT series.

3. Size Variations

Mud pump liners are available in various sizes to accommodate different pump configurations. The internal diameter, length, and wall thickness are critical parameters that must align with the pump’s specifications. Choosing the correct size is crucial to maintaining efficient fluid dynamics and minimizing wear on other pump components.

How to Choose the Right Liner

Selecting the appropriate mud pump liner requires a thorough understanding of operational requirements.

Factors such as drilling depth, geological conditions, and the composition of drilling fluids play a significant role in determining the best liner type. For shallow wells or projects with budget constraints, bi-metal liners may suffice. However, for deep wells or operations involving abrasive or corrosive fluids, ceramic liners are more suitable. Additionally, different models of mud pumps require compatible liners that match precisely in size and design to ensure optimal performance.

Sometimes, the benefits of investing in high-quality liners cannot be overstated. They significantly reduce maintenance downtime, extend the lifespan of mud pumps, and enhance overall drilling efficiency. In offshore drilling, where operational costs can reach upwards of $20,000 per hour, even a minor delay caused by liner failure can result in substantial financial losses. High-quality liners not only mitigate these risks but also contribute to the long-term profitability of drilling projects.

Conclusion

Understanding the types of mud pump liners and their specific applications is key to optimizing drilling operations. From single-metal liners for cost-conscious projects to advanced ceramic options for high-pressure environments, each type has its place in the industry. Moreover, selecting liners compatible with your mud pump model and ensuring the correct sizing are equally important considerations.

At SMKST, we pride ourselves on offering a comprehensive range of high-performance liners for F-series, 3NB-series, and other major pump models. With options tailored to meet diverse operational needs and the ability to customize liners based on your specifications, we provide cost-effective solutions that rival those of Western manufacturers. For inquiries and detailed product information, contact us today and ensure your drilling project is equipped for success.