Published on: Dec 10, 2024

In the oil and gas drilling industry, the mud pump is the core component of the entire drilling fluid circulation system, and the liner is a critical part of the mud pump. The liner’s primary role is to withstand high pressure and maintain a continuous flow of drilling mud. The pressure rating is a key parameter that measures the maximum pressure the liner can handle safely.

But why is the pressure rating so important? In deep wells or high-pressure drilling operations, the drilling fluid must overcome immense formation pressures. This means every component of the mud pump, including the liner, must endure these extreme conditions. The pressure rating not only determines the liner’s suitability for specific applications but also directly impacts the safety and efficiency of operations.

Whether you’re purchasing mud pump accessories or evaluating the performance of drilling equipment, the pressure rating of the liner is a vital specification to consider. Up next, SMKST’s drilling engineers will delve into the technical details, selection guidelines, and influencing factors of liner pressure ratings. This guide will help you choose the right liner tailored to your specific needs.

Working Principles and Importance of Mud Pump Liners

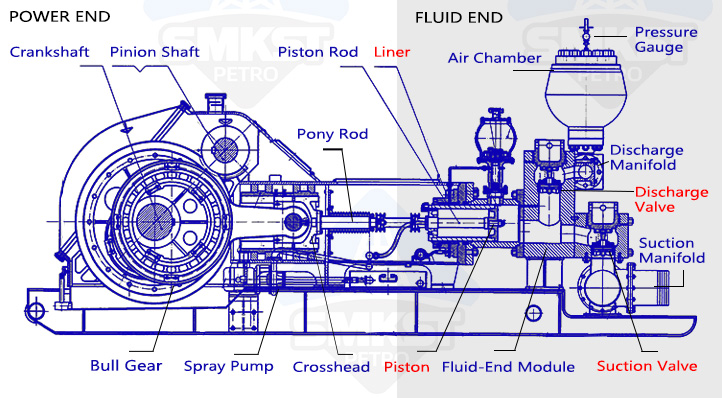

The mud pump liner plays a critical role in the circulation of drilling fluids. As the component that comes into closest contact with the piston, the liner endures high-intensity reciprocating movements while ensuring the stable output of mud under high pressure into the wellbore. To perform effectively, the liner must possess excellent pressure resistance, as well as abrasion and corrosion resistance, since drilling mud often contains particulates and chemical substances that can cause significant wear and corrosion.

1. Why Is the Pressure Rating Crucial?

In practical applications, the pressure requirements for drilling operations increase with well depth and formation pressures. For deep or high-pressure wells, insufficient liner pressure ratings can lead to several issues:

- Equipment Damage: The liner may crack or rupture under excessive pressure, leading to mud pump failure.

- Safety Risks: Leaks of high-pressure mud can result in onsite accidents, endangering personnel and equipment safety.

- Operational Interruptions: Liner failure may require downtime for repairs, delaying drilling schedules and increasing operational costs.

Thus, a liner’s pressure rating is not just a specification – it is a fundamental safeguard for ensuring smooth drilling operations.

2. How Is the Liner Pressure Rating Represented?

Liner pressure ratings are typically expressed in psi (pounds per square inch) or MPa (megapascals). Common ranges include 5,000 psi (approximately 34.5 MPa), 7,500 psi (approximately 51.7 MPa), or even higher. When selecting a pressure rating, it is essential to consider the current drilling environment and to allow for a safety margin to handle potential pressure surges.

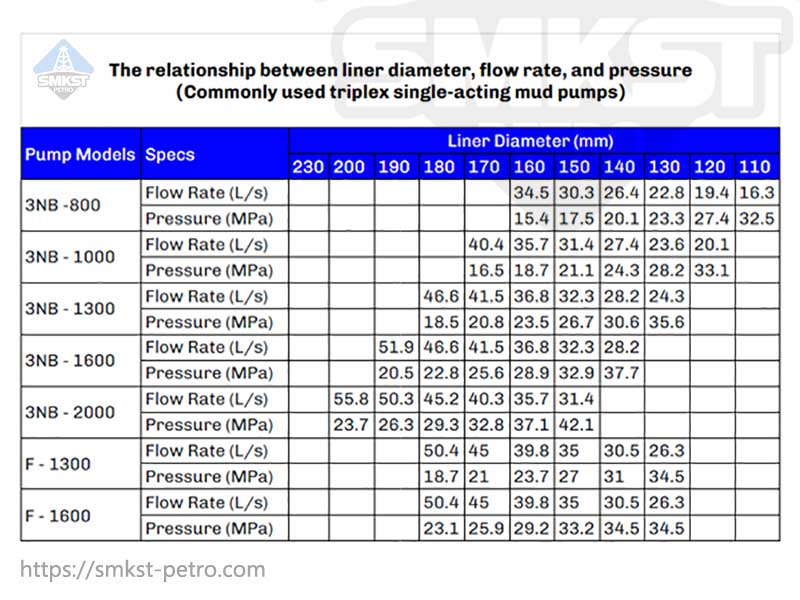

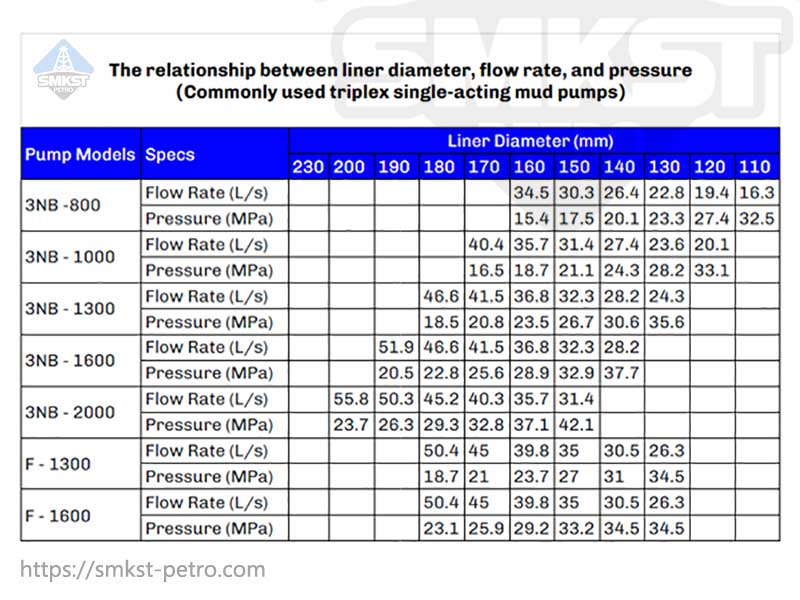

Mud Pump Liner Pressure Ratings Table

To provide a clearer understanding of mud pump liner pressure ratings, the following table showcases the relationship between liner diameter, flow rate, and pressure using the most commonly used triplex single-acting mud pumps in oil and gas drilling. Whether you’re working on shallow wells or high-pressure deep wells, this table serves as a reliable reference for equipment selection. (1 MPa ≈ 145 psi)

What Is the Right Liner Pressure Rating?

- Match Pressure Rating to Well Depth and Formation Pressure: For deep well operations, opt for high-pressure liners. For instance, the 110 mm liner of the 3NB-2000 pump can handle up to 42.1 MPa (approximately 6,100 psi), making it ideal for high-pressure drilling.

- Consider Flow Rate for Drilling Efficiency: Larger flow rates enhance drilling efficiency. For low-pressure, high-flow operations, select larger liner diameters. For example, the 230 mm liner of the 3NB-1600 pump delivers up to 51.9 L/s, suitable for shallow wells or fast drilling.

- Match Model to Operational Scenarios: Different models cater to varied scenarios. 3NB-800 is ideal for medium-to-low-pressure operations, with a maximum pressure of around 32.5 MPa (~4713 psi); F-1600 is designed for high-pressure operations, exceeding 34.5 MPa (~5003 psi), suitable for complex well conditions.

- Leave a Safety Margin for Pressure Fluctuations: Choose a liner with a slightly higher pressure rating than your actual operational needs to allow for short-term pressure surges. This ensures equipment safety and operational stability.

FAQ: Factors Influencing Liner Pressure Ratings

Several interconnected factors determine the pressure rating of a mud pump liner. Among these, material selection plays a crucial role.

- Common liner materials include high-strength alloy steel and ceramic, each offering unique benefits in terms of pressure resistance and wear resistance. Alloy steel provides excellent durability under high-pressure conditions, while ceramic excels in resisting abrasion and corrosion.

- Design structure is another important aspect that affects the liner’s pressure-bearing capacity. The wall thickness and machining precision of the liner are directly related to its ability to withstand high-pressure operations. Thicker walls and higher precision often result in greater durability and reliability.

- The operating environment also significantly impacts the pressure rating. High temperatures, corrosive substances, and fluctuating pressures can accelerate the wear and fatigue of the liner. These harsh conditions can compromise the liner’s integrity over time, making regular monitoring essential.

- Lastly, maintenance is key to preserving a liner’s performance. Routine inspections and timely upkeep can help detect early signs of wear or damage, ensuring that the liner continues to perform reliably throughout its operational life. Proper maintenance not only extends the liner’s lifespan but also minimizes unexpected downtime and associated costs.

Conclusion

The pressure rating of a liner is a critical metric for the performance and safety of a mud pump. Understanding its working principles, technical parameters, and influencing factors can help you maintain equipment stability in complex well conditions, optimize operational efficiency, and reduce costs and risks.

If you’re looking for API-standard high-quality mud pump liners, particularly cost-effective options from China, feel free to contact SMKST. We are committed to providing reliable solutions to clients worldwide, ensuring the success of your drilling operations!